In car part production hemming is used in assembly as a secondary operation after deep drawing trimming and flanging operations to join two sheet metal parts outer and inner together.

Aluminum sheet metal hem.

The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

Sheet metal hemming process finds its major applications in the manufacturing of parts pertaining to the automotive parts.

High gauge sheet metal is thicker than low gauge sheet metal which can make it difficult to manipulate using processes like hemming.

Abn sheet metal hand seamer 3 inch straight jaw manual metal bender tool sheet metal bending pliers flattening tool 4 5 out of 5 stars 144 27 89 27.

A seam is a method of joining two pieces of sheet metal together figure 5.

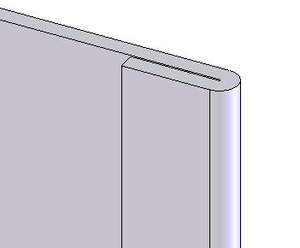

Hems can be useful as a way to stiffen a sheet metal panel.

This can be a serious problem because the inside of the hem is easy to wet but challenging to dry.

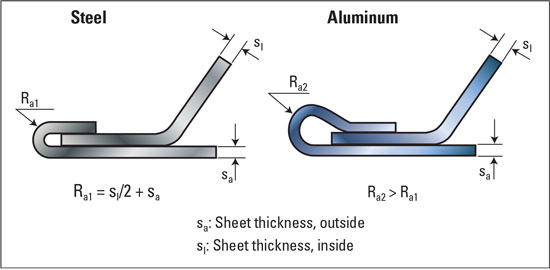

Minimum acute flat for aluminum mt x 2 minimum acute punch radius for aluminum minimum flat length x 2 hemming and seaming hemming and seaming are basically the same process.

Typical parts for this type of assembly are hoods doors trunk lids and fenders.

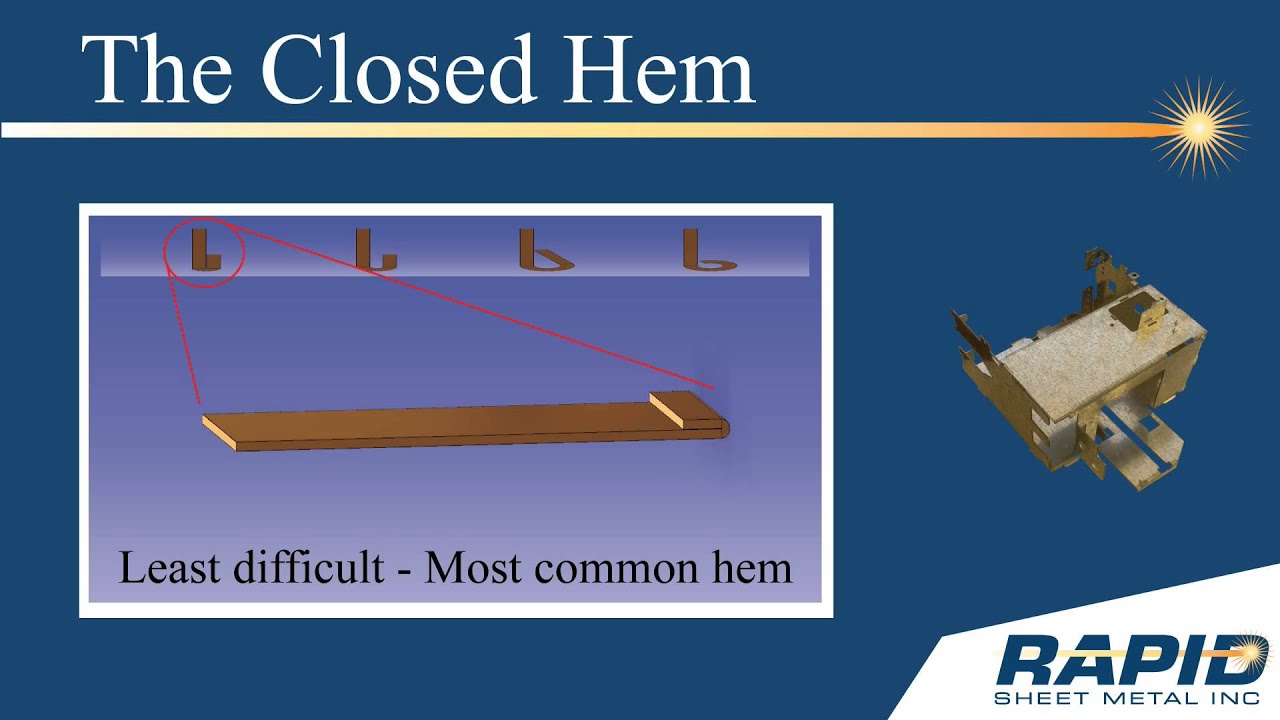

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself.

The gauge of course refers to the thickness of sheet metal.

When working with a brake press hems are always created in a two step process.

Hems have drawbacks however.

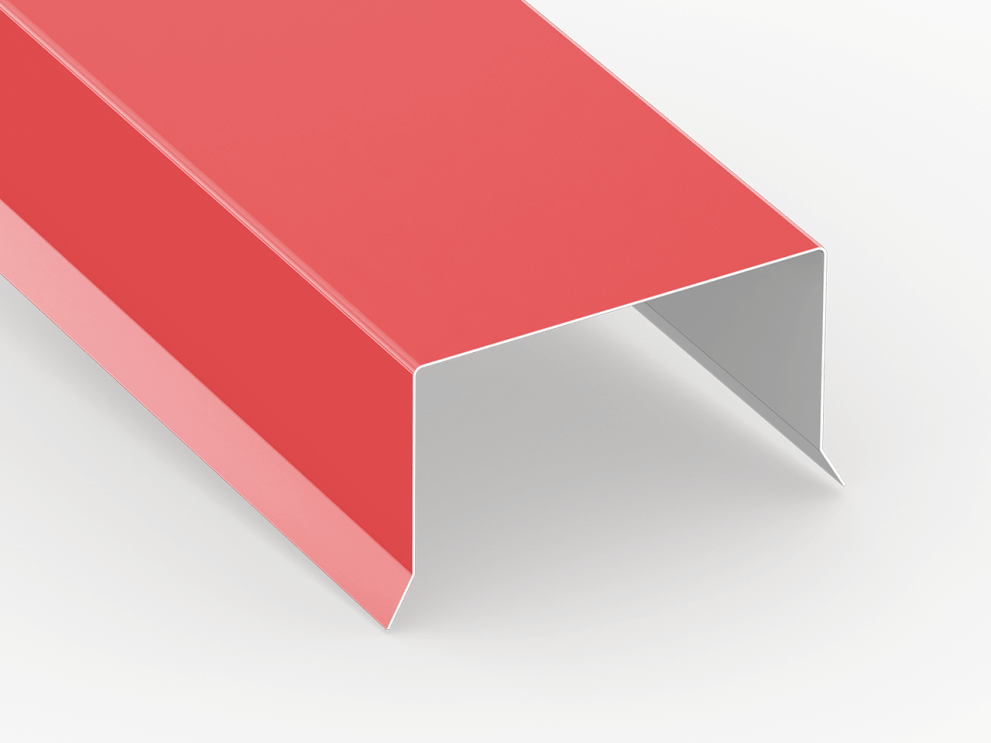

With the right tools however manufacturing companies can hem sheet metal by bending and rolling the edge over and onto itself.

Automotives parts such as deck lids trunk lids doors hoods and tailgates formed by hemming process requires sheet material to have high strength to weight ratio with excellent bending abilities without crack and fracture.

Hemming is the process in which the edge is rolled flush to itself while a seam joins the edges of two materials.

Hemming is a metalworking process where a sheet metal edge is mechanically bent to fit an uneven surface or simply roll over onto itself.

With plated steel parts the interior of the hem can be very difficult to cover for corrosion control.

Hems are commonly used to reinforce an edge hide burrs and rough edges and improve appearance.

The hem is primarily used for reinforcement safety and edge appearance figure 4.

And while hems or seams reinforce a sheet metal edge their main purpose is to improve appearance by hiding burrs and rough edges on metal back splashes and other sheet metal installations.